SCR™Scraped Solvent Recycling

The SCR™ Series solvent reclamation system, designed for solids content up to 20%, incorporates PRI’s rotating scraper blade assembly to achieve efficient, consistent clean solvent production throughout the solvent reclamation process. Safety and efficiency are at the heart of SCR™’s design.

SCR™

Scraped Solvent Distillation System

The SCR™ solvent distillation system is the most durable, reliable, and safe system on the market. The scrape-sided Solvent Recycling System allows you to recover waste solvent, reducing waste and cost.

Maximize Solvent Recovery:

- cut virgin solvent purchase volumes

- reclamation rates as much as 90%

- reduce hazardous waste disposal volume

- units typically pay for themselves in a few months

Reduced Environmental Impact & Increased Safety:

- reduce the risks associated with large volumes of hazardous waste

- reduce your facility’s environmental footprint

Durable, Reliable, and Protected

PRI 10 Year Standard Limited Warranty

PRI solvent recovery systems carry the lowest life-cycle cost in the industry; over 75% of units sold in the last 15 years are still in service.

With proper care and maintenance, a PRI solvent recycling system can last for decades. That’s why we’re not afraid to back it up with a 10-year limited warranty on the distillation vessel. With PRI, you can trust that your solvent distillation system will be running for years to come.

Safe, Easy to Use.

Still Bottoms Safety Discharge Package

Our solvent reclamation systems are designed for precise control and safe use, processing virtually any flammable or combustible solvent waste, including reactive chemistries such as waste containing nitrocellulose or cross-linking resins.

Our safety discharge package allows operators to easily discharge distillation bottoms. Our Still Bottoms Discharge Safety Kit includes:

- Drum positioning ring for proper alignment

- Drum cart to easily position the drum

- Drum-in-place sensor prevents discharge without drum

- Drum full sensor assists operator, prevents overfill

- Safety interlocks to the dump mechanism

- Rear vent opening to exhaust fumes away from operator

Long-Term, Consistent Output

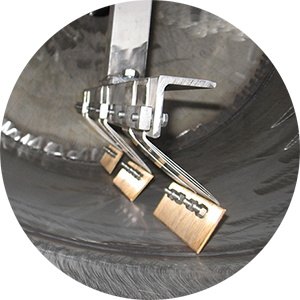

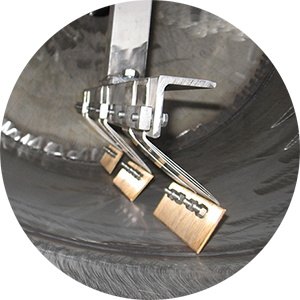

Scraper Blade Assembly

The SCR solvent recycling system is designed for maximum efficiency. Our patented rotating scraper blade assembly:

- cleans the heat transfer surface of sludge buildup for high efficiency

- all the heat transfer area below the liquid operation level is cleaned

- solids are rolled off the side walls and down into the conical bottom, speeding up the solvent distillation process

- gently agitates and mixes the contents of the solvent distillation vessel

Available Models:

| MODELS | CAPACITY | RATE | WEIGHT |

| SCR-200 | 280 L (74G) |

76/Lh (20 G/h) |

1361 kg (3,000 lbs) |

| SCR-250 | 450 L (119 G) |

106/Lh (28 G/h) |

1451 kg (3,200 lbs) |

| SCR-350 | 768 L (203 G) |

161/Lh (43 G/h) |

2268 kg (5,000 lbs) |

| SCR-400 | 1192 L (315 G) |

225/Lh (60 G/h) |

2585 kg (5,700 lbs) |

| SCR-450 | 1627 L (430 G) |

284/Lh (75 G/h) |

2722 kg (6,000 lbs) |

| SCR-550 | 3051 L (806 G) |

435/Lh (115 G/h) |

3629 kg (8,000 lbs) |

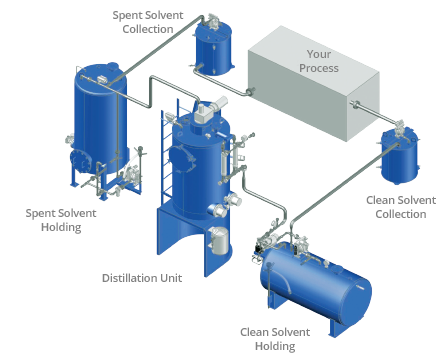

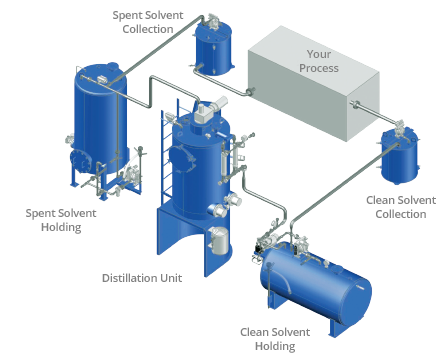

Closed-Loop Solvent Recycling

Spent solvent collection, distillation, and clean solvent holding. Directly integrated into your process.

Our solvent recovery systems are often incorporated into a complete closed-loop solvent management system, utilizing PRI’s specialized and custom-designed Clean and Dirty Solvent Tanks with feeds.

In a closed-loop process, waste solvent is collected in a Dirty Solvent Tank, then piped to a Distillation System to separate the contaminants. Then, contaminants are discarded and reusable solvent is automatically sent to a Clean Solvent Tank, which feeds your production process. PRI can engineer solvent management systems to support parts washing, paint lines or other manufacturing processes where solvents are used.